Testing Process – Ragnar Metals & Tubes

At Ragnar Metals & Tubes , our testing process is integral to ensuring the reliability, safety, and performance of our wide range of products, including pipes and tubes, Fittings, Flanges, Sheets & Plates, Fasteners, and Rods & Bars. Each product undergoes a series of stringent quality checks and inspections, starting from raw material verification to final dispatch. We follow internationally recognized testing standards such as ASTM, ASME, ISO, and DIN to ensure each product meets or exceeds required specifications.

Our standard test procedures include chemical composition analysis using spectrometers to confirm material grade and compliance. Mechanical tests such as tensile strength, yield strength, elongation, and hardness testing are conducted to evaluate the physical properties of materials. For pressure-bearing items like pipes, tubes, and flanges, we also perform hydrostatic testing and pneumatic testing to ensure leakage-proof performance.

In addition, non-destructive testing (NDT) methods such as ultrasonic testing (UT), dye penetrant testing (DPT), radiographic testing (RT), and magnetic particle testing (MPT) are employed as per customer requirements to detect any internal or surface-level defects without damaging the material. Dimensional inspection using calibrated gauges and precision tools is also a routine part of our testing protocol.

Through detailed documentation and quality traceability, every batch is certified and supported with test reports (Mill Test Certificates or MTCs), ensuring full transparency. Our testing facilities are regularly upgraded, and staff are trained to stay in line with industry advancements, reinforcing Ragnar metals & tubes’ unwavering focus on product excellence and customer trust.

Certificates

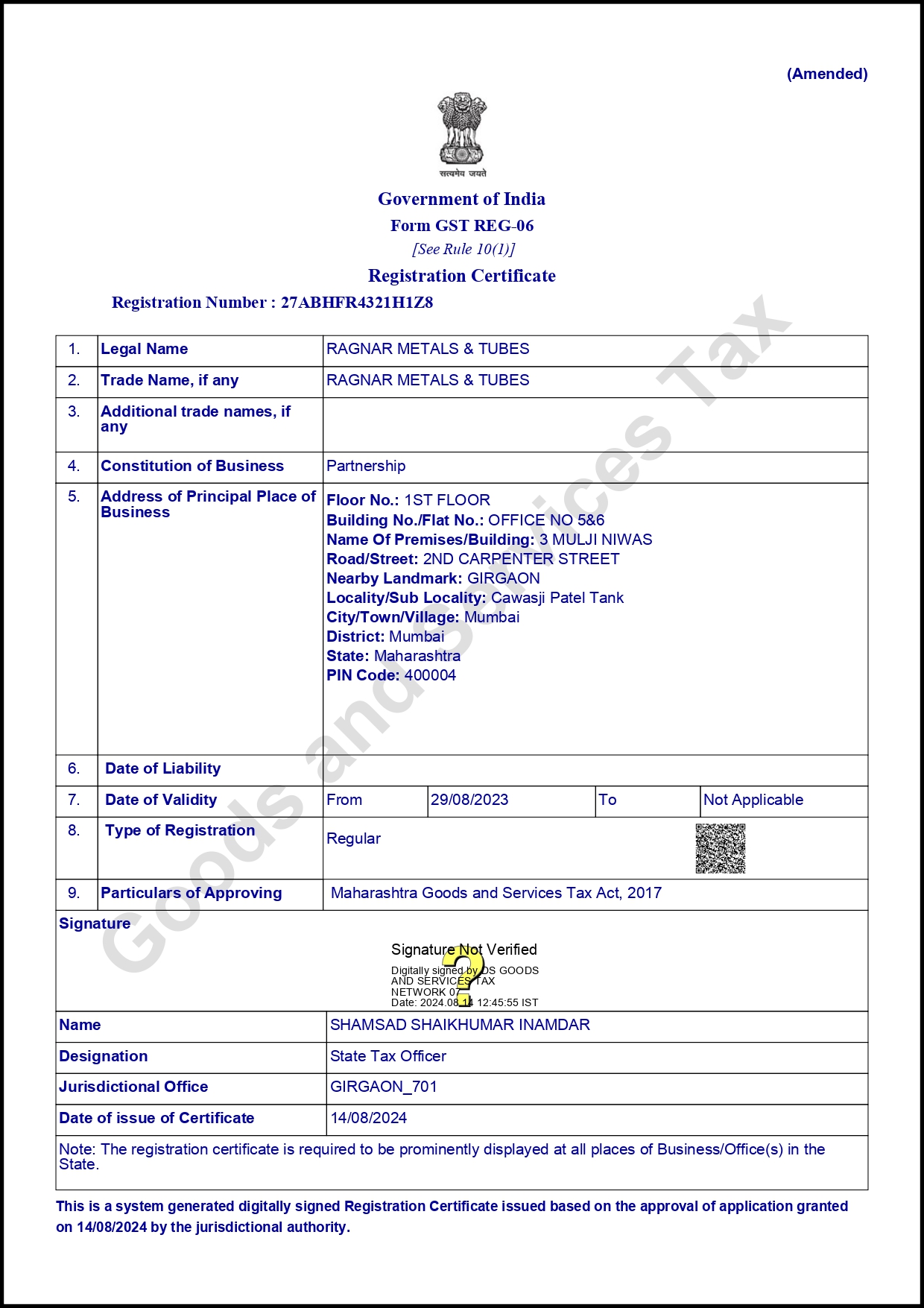

GST Registered Company

Fully compliant with Indian tax regulations for transparent domestic and international trade.

Download Certificate

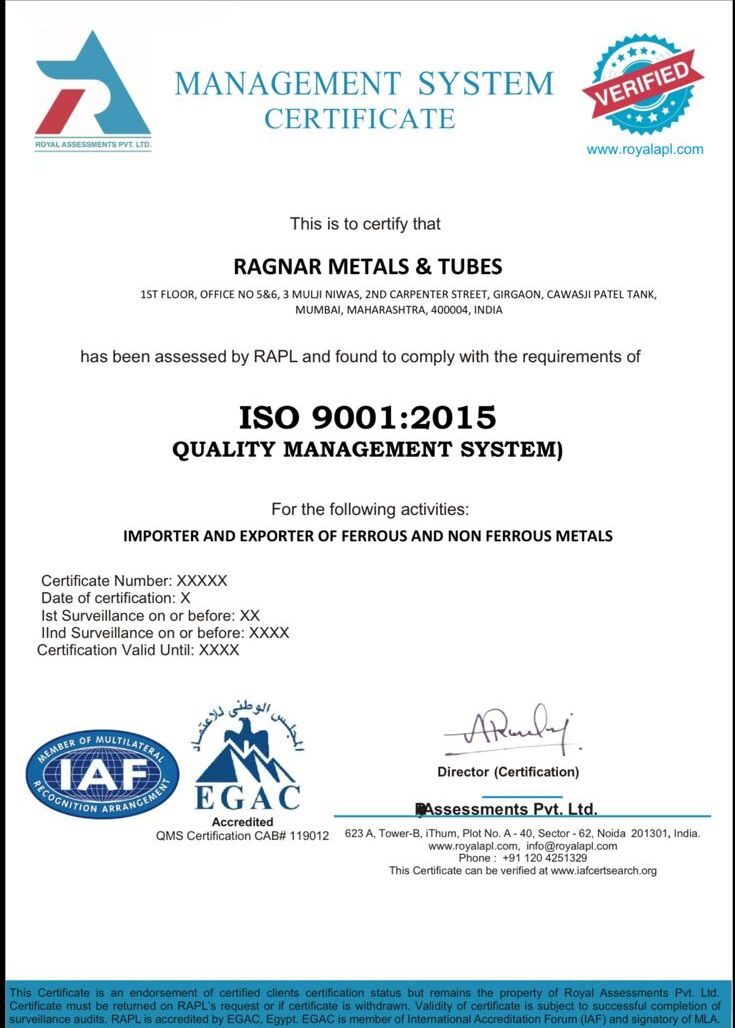

ISO 9001:2015 Certified

Quality management system ensuring consistent manufacturing and inspection standards.

Download Certificate

ISO 1002:2018 Certified

Certified for international quality compliance, safety, and global export documentation standards.

Download Certificate

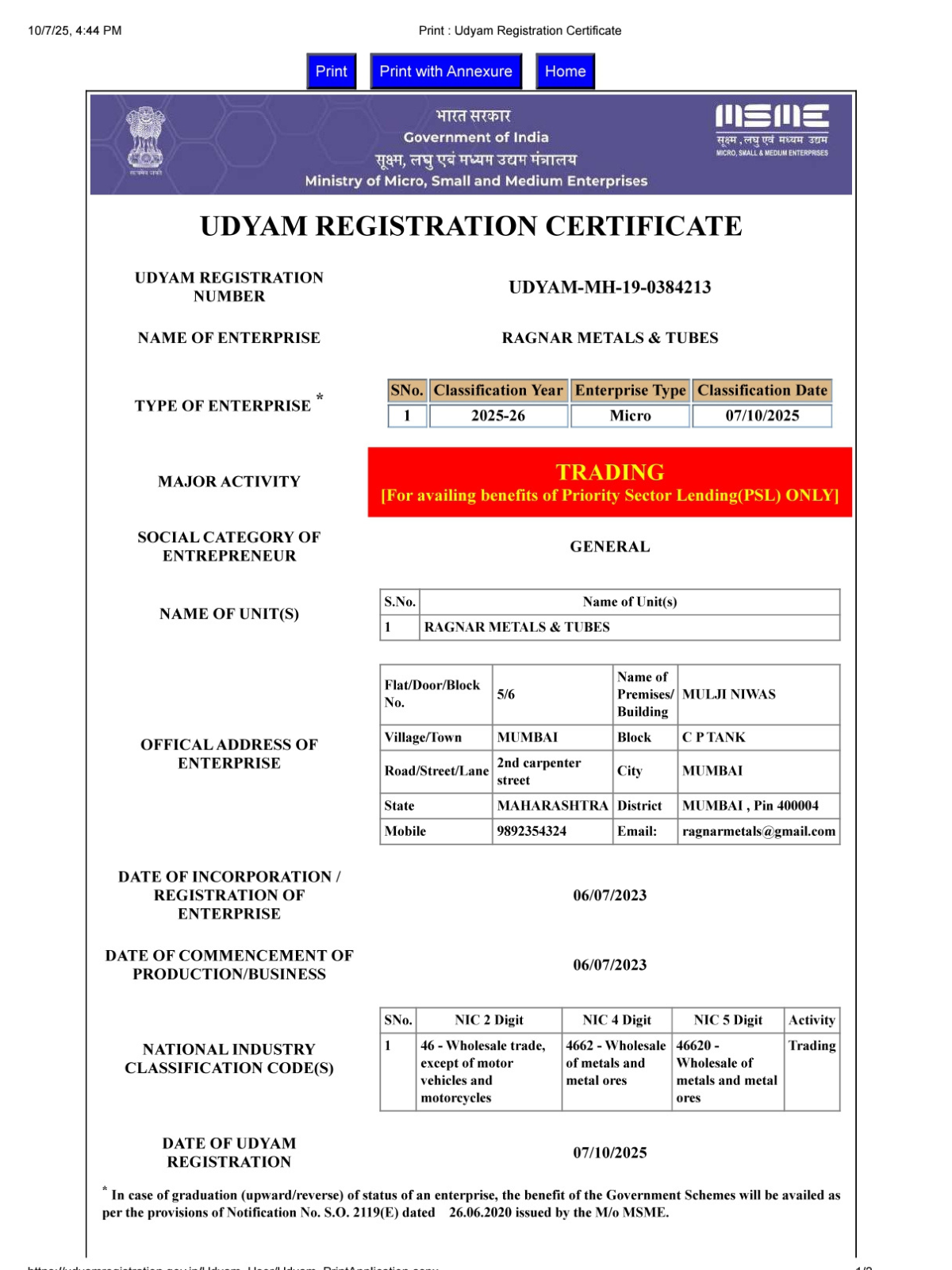

MSME / Udyam Registered

Government-recognized MSME supporting trusted sourcing and project compliance.

Download CertificateTypes of Test

Why Choose Ragnar Metals & Tubes

- ✔ Over a decade of industry experience

- ✔ Certified raw materials with full traceability

- ✔ Third-party inspection support (SGS / TUV)

- ✔ Mill Test Certificates (EN 10204 3.1)

- ✔ Trusted exporter to global industries

.jpg)

.png)